Technologies

Combined heat and power (CHP) plant

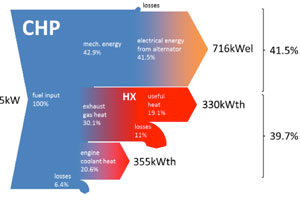

Biogas produced in anaerobic digestion can be valorised on-site in combined heat and power (CHP) plants. These units burn biogas of different quality and convert it into electricity and heat, reaching a high total utilisation efficiency of the energy content in the biogas. CHP plants at WWTPs are usually gas motors, which drive a generator for electricity generation with electrical efficiencies of 35-44% depending on size and load rate. Heat is supplied at two distinct temperature levels: the cooling cycle of the gas motor typically supplies heat at 90°C, while exhaust gas contains heat at >350°C.

Both types of heat can be utilised with heat exchangers, e.g. for heating of anaerobic digestor or buildings or to supply heat for additional processes at the WWTP (e.g. stripping, thermal hydrolysis). Thermal efficiency of usable heat is 41-50% and typically adds up to 85-90% with electrical efficiency. CHP plants should be operated with relatively constant gas quality and in an optimum load range to prevent loss in efficiency.

- Full-scale technico-economical performances of options for heat to electricity conversion in WWTP

- International Energy Agency Report on Combined Heat and Power

- Evaluation of Combined Heat and Power Technologies for Wastewater Facilities

-

Purpose

-

Approach

-

Where?

Gas boiler

This technology was not part of the POWERSTEP project.

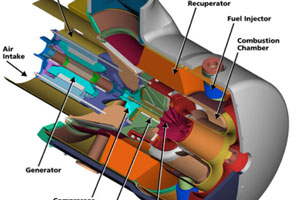

Microgas turbine

This technology was not part of the POWERSTEP project.

-

Purpose

-

Approach

-

Where?