SIDESTREAM N REMOVAL OR RECOVERY

Sludge dewatering effluent contains high concentrations of ammonia, originating from anaerobic digestion of organic matter. This sidestream is usually recycled to the inlet of the WWTP, increasing the load to the treatment plant and related energy demand. It can also be treated in a separate process for N removal, which can be more efficient than mainstream treatment due to high concentrations and elevated temperature of the sludge water.

Different options are available for sidestream N removal, such as biological nitrification and denitrification, nitritation, deammonification, or stripping. The latter process even enables N recycling, fixing the nitrogen in a liquid or solid product which can then be sold as N fertiliser.

Technologies

Air stripping

Sludge liquor from dewatering of digested sludge contains a high load of nitrogen, which is recycled back to the inlet of the WWTP. This return load usually contributes 10-20% of the total nitrogen load of the plant. It can be reduced by dedicated N removal in this sidestream, which can be realised by different processes. Apart from biological processes which eliminate the nitrogen into the atmosphere, ammonia can also be stripped in suitable conditions of high pH and temperature and then be recovered in an acidic solution, which can finally be used as liquid fertiliser.

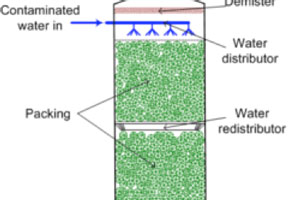

Air stripping is a proven technology which utilises ambient air to strip ammonia in a first stripper column, which is then recovered into sulfuric acid in a second column. Air stripping is typically operated at 70°C and pH 10 in columns filled with carrier material to enhance surface area for gas-liquid transfer. Air stripping is most cost-effective at high ammonia concentrations and is limited to a maximum elimination of nitrogen due to the chemical equilibrium of ammonia.

-

Purpose

-

Approach

-

Where?

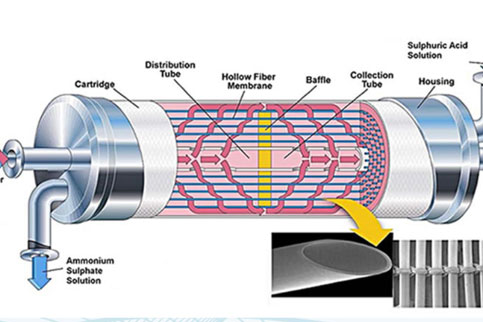

Membrane stripping

Sludge liquor from sludge dewatering is usually heavily loaded with nitrogen and contributes significantly to the nitrogen load of the WWTP. Beside biological processes for sidestream N removal (e.g. deammonification) which can have issues in process stability, N can also be removed by air, steam or membrane stripping in a physico-chemical process, thus enabling the recovery of nitrogen as a valuable liquid fertiliser (ammonium sulfate). Membrane stripping represents a compact and cost-effective method to recover the nitrogen in sludge liquors by gas-permeable membranes. To convert nitrogen into free ammonia and enable stripping, pH and/or temperature of the sludge liquor have to be increased.

Optimising pH control (e.g. by CO2 stripping combined with some caustic) and temperature conditions minimises the efforts in heat and chemical costs, and allows cost-effective operation of membrane stripping. Pre-treatment of the sludge liquor with coagulation/filtration also has to guarantee particle-free influent to the membrane in order to protect the membrane module from mechanical damage and clogging.

- Full-scale implementation of membrane stripping

- Sustec: supplier of membrane stripping plants

- BLUEtec: supplier of membrane stripping plants

- Gebr. Kunst: supplier of membrane stripping plants