Efficient aeration

Aeration of the biological stage is the major driver for energy demand at a WWTP, typically accounting for 40-60% of the total electricity demand. Hence, improving the efficiency of aeration is a key measure to reduce electricity consumption and related costs of WWTP operation. Aeration efficiency can be increased by improving the transfer of oxygen from the gas into the liquid phase, e.g. by replacing mechanical surface aerators or upgrading bubble aeration with new diffusors for fine-bubble aeration.

In addition, aeration demand can be more precisely adjusted to the actual requirements of the biological process with frequency-controlled blowers and online aeration control based on automatic sensors for dissolved oxygen and ammonia.

-

What purposes?

-

Which technologies?

-

Where?

Enhanced C extraction

Municipal wastewater contains a variety of organic substances, and the embodied carbon represents a potential source of chemical energy. Traditional WWTPs separate a fraction of this carbon (up to 50%) into primary and excess sludge, while the remaining part is converted to CO2 in biological treatment by microbial biomass. The latter part requires a high amount of electricity for oxygen supply, and wastes the potential energy contained in this part of the organic matter.

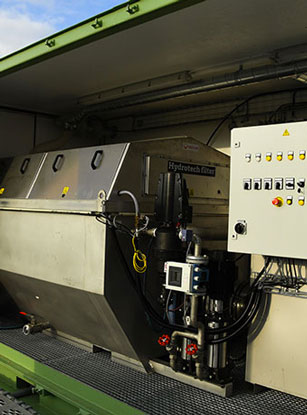

Enhancing the extraction of carbon into sewage sludge in the WWTP process will increase the potential biogas yield and decrease efforts for treatment, thus improving the overall energy profile of the WWTP considerably. Enhanced carbon extraction can be realised by advanced primary treatment combining chemical dosing with sedimentation, filtration or flotation processes to separate most of the particulate matter. After enhanced carbon extraction for energy recovery, downstream biological nitrogen removal has to be optimised to safely fulfil effluent quality targets.

-

What purposes?

-

Which technologies?

-

Where?

Heat-to-power

At a WWTP, heat is mainly required to heat the digestor which operate at temperatures between 35-38°C, but also for heating of buildings or specific processes such as ammonia stripping. Heat is also produced on-site in CHP plants or gas boilers, which are usually operated with the biogas produced in anaerobic digestion. The overall heat balance of a typical WWTP is often positive, meaning that excess heat is blown into the air because it exceeds the demand on-site, and heat sale to external customers is not feasible.

This excess heat can be partially valorised with processes that turn heat into electricity (“heat-to-power”), drawing on excess or low-grade heat of the WWTP and increasing electricity production at the plant. Available technologies for heat-to-power include steam or organic rankine cycle units, or thermoelectric generators. The economic feasibility of these units also depends on the actual seasonal heat profile of the WWTP with varying amount of excess heat in summer and winter operation.

-

What purposes?

-

Which technologies?

-

Where?

Improved digestion

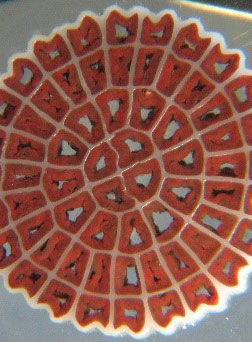

Sewage sludge is often stabilised by anaerobic digestion, reducing the organic matter and converting it into biogas. This process is usually operated in a digestor, where sludge is heated to mesophilic conditions (35-38°C) and digested for up to 20 days. With this process setup, a conversion of up to 50% of organic matter is typically achieved.

Several options are available to increase this conversion ratio, produce more biogas from sludge and reduce final sludge cake for disposal. Digestion process can be operated in two dedicated stages or in cascading design, optimising process efficiency and capacity utilisation. Sludge can also be treated thermally or chemically before digestion to improve hydrolysis and increase degradation. Improved digestion can also have an effect on the return load from sludge dewatering, which has to be taken into account in an overall concept for optimised sludge management.

-

What purposes?

-

Which technologies?

-

Where?

Low-carbon N removal

The removal of nitrogen at a WWTP is realised in biological processes, where the dissolved ammonia is converted to gaseous N2 by microbial activity. The conventional process consists of the steps of nitrification and denitrification, converting ammonia to nitrate and then nitrate to gaseous N2. This process requires a high amount of oxygen for nitrification, and a carbon source for denitrification. Both aspects have a high impact on the overall energy balance, as oxygen supply needs electricity and carbon consumed during denitrification is not available for biogas production.

If enhanced carbon extraction is targeted in primary treatment, a strategy for low-carbon N removal (i.e. without external carbon source) is required. Advanced control of WWTP operation based on online sensors and effluent quality can help to optimise the utilisation of residual carbon, thus enabling a sufficient degree of N removal with the remaining carbon source. Another potential approach involves a switch of the biological process to promote a combination of nitritation (ammonia to nitrite) and anammox bacteria, which can convert nitrite and ammonia to N2 without using a carbon source. This process has already been realised in full-scale for sidestream treatment where high ammonia concentration and high temperature provide favourable conditions for these bacteria.

The application of nitritation/anammox in mainstream (“mainstream anammox”) is more challenging due to less favourable conditions such as low temperature and high dilution, but has been tested and optimised in industrial pilot scale to fulfil effluent quality requirements. This form of low-carbon N removal will enable the operation of new WWTP schemes where enhanced carbon extraction delivers a high yield of biogas and mainstream anammox as secondary treatment can still remove nitrogen below target values.

-

What purposes?

-

Which technologies?

-

Where?

N recovery

Nitrogen contained in municipal wastewater can partially be recovered at a WWTP, enabling the recycling of this valuable plant nutrient to agriculture. N recovery is currently feasible only in highly concentrated streams such as sludge dewatering effluent, where ammonia concentrations can be very high.

Suitable processes for N recovery from this sidestream are mainly based on physico-chemical processes such as air stripping or membrane stripping. Both processes rely on the transfer of gaseous NH3 into sulfuric acid, resulting in a liquid diammonium sulfate solution which can be sold as fertiliser.

-

What purposes?

-

Which technologies?

-

Where?

N Removal

Nitrogen in sludge dewatering effluent represents a highly concentrated sidestream at a WWTP, which is usually recycled to the inlet of the plant and contributes significantly to the total nitrogen load of the mainline (up to 20%). This sidestream can be separately treated for N removal using different biological or physico-chemical processes.

Biological processes include conventional nitrification combined with denitrification, but this process requires high amount of oxygen and a carbon source. Deammonification applies two steps of nitritation and anammox, converting ammonia to gaseous nitrogen without the need of an external carbon source. Eventually, nitrogen conversion can also be stopped at nitrite (nitritation) to recycle the chemically bound oxygen to the mainline, using mainstream carbon for N removal.

-

What purposes?

-

Which technologies?

-

Where?

Power-to-gas

Biogas produced in anaerobic digestion contains around 60% methane and 40% CO2. While methane can be readily utilised as fuel for CHP plants or directly injected into the gas grid, CO2 cannot be valorised and is usually emitted to the atmosphere. Using a power-to-gas (P2G) technology, this CO2 could also be converted into valuable biomethane by methanation.

This process describes the conversion of CO2 and hydrogen into methane, which can be realised by catalytic or biological processes. Hydrogen can be produced with an electrolyser operated during times of low electricity prices, producing H2 and O2 from water. While H2 is used for methanation, O2 and excess heat of the electrolyser can be used on-site to cover the internal demand of oxygen for the activated sludge system or to provide heat to the WWTP. The use of a P2G plant enables the integration of WWTP infrastructure into the dynamic energy market of the future and optimises economic revenues from biogas production.

-

What purposes?

-

Which technologies?

-

Where?

SIDESTREAM N REMOVAL OR RECOVERY

Sludge dewatering effluent contains high concentrations of ammonia, originating from anaerobic digestion of organic matter. This sidestream is usually recycled to the inlet of the WWTP, increasing the load to the treatment plant and related energy demand. It can also be treated in a separate process for N removal, which can be more efficient than mainstream treatment due to high concentrations and elevated temperature of the sludge water.

Different options are available for sidestream N removal, such as biological nitrification and denitrification, nitritation, deammonification, or stripping. The latter process even enables N recycling, fixing the nitrogen in a liquid or solid product which can then be sold as N fertiliser.