Technologies

Biological methanation

Biological methanation uses specific microbial metabolisms to generate biomethane out of CO2 and hydrogen. Archaea bacteria are capable to realise this conversion, using CO2 from biogas upgrading and H2 from water electrolysis. The technology has been realised in pilot and full-scale plants up to 1MW of electrical power in electrolysis. The reactor design is crucial for an efficient process to overcome the physical challenge of dissolving H2 into water. The process is scalable and can be operated at full or part-load with short start-up times, operating either on biogas directly or on CO2 from biogas upgrading.

The produced biomethane can be injected to the gas grid for large-scale and long-term storage or used locally, e.g. as fuel for transportation. Besides the energy storage aspect, biological methanation contributes to CO2 recycling, and electrolysis generates valuable by-products such as oxygen and heat at 65oC for direct use at the WWTP.

Catalytical methanation

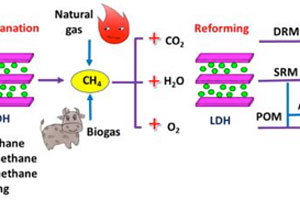

Biogas produced in anaerobic digestion of sewage sludge contains 60-65% methane and 30-35% CO2. If CO2 is separated from biomethane in an upgrading step, it can be used in a Power-to-Gas approach to be converted to biomethane. Utilising hydrogen which is produced in an electrolyser, the process of methanation converts H2 and CO2 into CH4 (Sabatier reaction).

Methanation can be reached in a physico-chemical process with catalytic methanation, or using microbial activity in bio-methanation. Catalytic methanation uses a metal catalyst to enable the chemical reaction, but requires high temperature (350-550°C) and pressure (1-100 bar) and is affected negatively by gas impurities. Currently, catalytic methanation is limited to a CO2 conversion of ca. 80%. Full-scale application of catalytic methanation is still under development, and different reactor configurations and operating modes are tested.

- Sunfire: supplier of catalytic methanation

- Topsoe: supplier of catalytic methanation

- Johnson Matthey: supplier of catalytic methanation

- Methanation in HELMETH Project

- Audi e-gas

- Review paper on methanation technologies

- Review of methanation

- Comparison of biological and catalytic methanation (in German)

- Methanation of CO2 - storage of renewable energy in a gas distribution system

-

Purpose

-

Approach

-

>Where?

Gas scrubbing

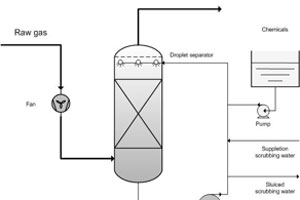

Biogas from anaerobic digestion of sewage sludge contains around 60-65% of methane, 30-35% CO¬2, and other impurities such as N2, H2S, and siloxanes. An alternative to valorisation of this biogas onsite (e.g. in a CHP plant) is the direct injection of gas into the public grid as biomethane. However, gas quality of the injected biomethane has to comply with defined standards of the gas grid operator. A high heating value requires a concentration of >95 Vol-% of methane in the injected gas. This can be achieved by gas scrubbing, which describes the separation of methane and CO2 in a physico-chemical process.

Gas scrubbing can be realised with adsorption using water, amine or other organic scrubbers or pressure-swing adsorption on activated carbon or zeolite. More recently, membrane-based scrubbing or cryogenic scrubbing have been developed. Important features of scrubbers are working pressure and related energy demand, methane content in upgraded gas and methane losses, and heat requirement. Before gas injection, further cleaning can be necessary to remove impurities such as H2S, siloxanes, and other hydrocarbons.

- Report on biogas upgrading technologies (IEA Bioenergy)

- Report on biogas upgrading technologies (SGC)

- Report on biogas upgrading technologies (Energiforsk)

- Gas scrubbing - general

-

Purpose

-

Approach

-

Where?