Technologies

Activated sludge

The process of activated sludge has been developed more than 100 years ago. It is based on the removal of dissolved substances from wastewater using suspended microbial biomass (“activated sludge”). Using the metabolism of the microbial biomass, organic matter and other pollutants such as nitrogen and phosphorus are eliminated to atmosphere or transferred into the biomass. This process requires large amounts of oxygen, which is supplied to the biomass by introducing air into the system. Aeration can be realised by e.g. bubble diffusors or surface aerators, and aeration efficiency is a major cost factor for WWTP operation.

While most of the biological sludge is separated from purified water in a final sedimentation tank (clarifier) and recirculated to the activated sludge process, a fraction of the surplus sludge is separated as excess sludge from the treatment process. There are multiple configurations for activated sludge systems to enable the enrichment of specific microbial groups for elimination of nitrogen and phosphorus. Sludge age, biomass concentration and oxygen conditions are major parameters to be adjusted in an activated sludge systems to guarantee the desired capacity of the treatment process.

-

Purpose

-

Approach

-

Where?

Advanced control

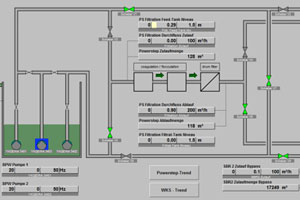

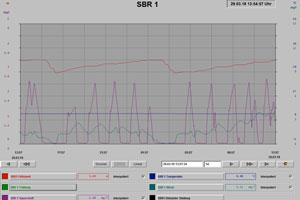

After advanced primary treatment to remove a large fraction of COD, the remaining wastewater has a low COD/N ratio. Hence, optimal usage of the remaining carbon is vital to reach stable denitrification capacity in the biological step. This can be reached in SBR-type WWTPs by applying advanced control strategies at the WWTP process control system: in standard operation, an adapted feeding and aeration regime of the SBR can optimise the denitrification capacity, while dedicated backup strategies triggered by an increase in nitrate concentrations in the SBR can help to keep effluent TN values below the target.

For standard operation this means that SBR is mainly fed in denitrification phases, and aeration is controlled by oxygen depletion rate instead of time. Backup strategies include reducing COD extraction in primary treatment (reduction of chemical dosing, bypassing primary treatment) or utilising other available carbon sources (supernatant of sludge thickening, acetate dosing). For advanced control strategies, online monitoring of nitrate is required, while online monitoring of ammonium is recommended as well.

Clarifier

Deammonification

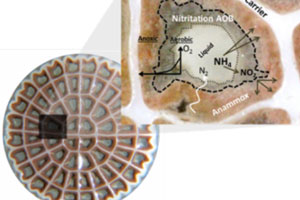

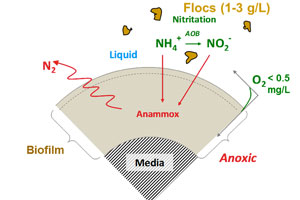

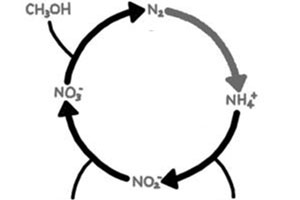

Deammonification is the process of nitritation-anammox and is a shortcut in the conventional nitrification/denitrification process. Deammonification is performed in two steps: aerobic nitritation, where slightly more than half of the ammonia is oxidised to nitrite by ammonia oxidising bacteria (AOB) and anoxic ammonia oxidation, where ammonia and nitrite are converted by anammox bacteria to nitrogen gas. Compared to conventional nitrogen removal process, no organic carbon is required for nitrogen removal and large savings of oxygen and energy demand can be achieved.

Deammonification process can be configured in one or two reactors. Performing deammonification in two reactors, where aerobic nitritation and anoxic ammonium oxidation are performed separately, gives better possibilities for optimising the growth conditions for AOB and anammox bacteria. On the other hand, deammonification in one single reactor benefits from generally lower investment costs and lower demand for operational maintenance. To allow simultaneous nitritation and anammox process, one stage deammonification is carried out in biofilms, where the biofilm can grow on carriers, or be in granules or flocs. In the biofilm, the AOB are enriched in the outer layer of the biofilm and the anammox bacteria in the anoxic inner layer of the biofilm. Specific operational conditions (pH, temperature, oxygen level) are maintained within the reactor to allow the process specific bacteria to grow in the biofilm.

Deammonification for side-stream treatment is a state of art technology, where high ammonia concentration with low COD concentration are typical characteristics of the side-stream water from dewatering of digested sludge. This reject water is usually sent back to the main treatment line, where the treatment of this ammonia load through conventional nitrification/denitrification can be quite cost-intensive. The use of deammonification process on side-stream water can dramatically reduce the nitrogen load on the existing biological treatment line. It is also a way to treat a part of the nitrogen at a low energy. In addition, since it allows a reduction of the nitrogen load on the main treatment line, it is also a solution to upgrade an overloaded existing wastewater treatment plant at a low cost.

Mainstream Anammox (1-stage)

Deammonification is the process of nitritation-anammox and is a shortcut in the conventional nitrification/denitrification process. Deammonification is performed in two steps: aerobic nitritation, where slightly more than half of the ammonia is oxidised to nitrite by ammonia oxidising bacteria (AOB) and anoxic ammonia oxidation, where ammonia and nitrite are converted by anammox bacteria to nitrogen gas. Compared to conventional nitrogen removal process, no organic carbon is required for nitrogen removal and large savings of oxygen and energy demand can be achieved. The slow-growing bacteria in deammonification are generally grown in biofilms on carriers (as part of the MBBR technology) or in granules and/or flocs.

Today, deammonification technologies for side-stream treatment are state-of-the-art. However, the application of deammonification on mainstream municipal effluent faces several challenges, due to the low temperature, low ammonia concentration and higher COD/NH4-N ratios, which result in competition between the different bacterial consortiums (AOB, Nitrite Oxidising Bacteria (NOB), anammox bacteria and heterotrophs (OHO)), and the requirements for an efficient NOB repression strategy.

One approach for implementation of deammonification in the mainstream is the one-stage Integrated Fixed Film Activated Sludge (IFAS) process, which consists of a Moving Bed Biofilm Reactor (MBBR) with the addition of an external settler for sludge retention. With this configuration, anammox bacteria preferentially grow in the biofilm on the carriers while the aerobic AOB tend to grow in the suspended sludge. The integration of activated sludge and biofilm is an effective approach to improve single-stage biofilm deammonification processes, as suspended growth is capable of enriching nitrifiers and improving the rate of nitritation at low DO levels due to less limitation on mass transfer, while carriers with anammox biomass are easily and securely retained in the reactor.

For mainstream deammonification applications, the IFAS configuration provides fast and robust physical separation between anammox-rich biofilm carriers and nitrifier-rich suspended sludge, which allows for easy control of the sludge age in the system and therefore efficient selective wash-out of NOB while retaining anammox. The IFAS configuration also has the advantage of being more tolerant towards soluble biodegradable COD (sbCOD), making it possible to handle an influent with a relatively high sbCOD/NH4-N ratio. Additionally, the IFAS configuration can be readily retrofitted into existing activated sludge systems.

Mainstream Anammox (2-stage)

Deammonification is the process of nitritation-anammox and is a shortcut in the conventional nitrification/denitrification process. Deammonification is performed in two steps: aerobic nitritation, where slightly more than half of the ammonia is oxidised to nitrite by ammonia oxidising bacteria (AOB) and anoxic ammonia oxidation, where ammonia and nitrite are converted by anammox bacteria to nitrogen gas. Compared to conventional nitrogen removal process, no organic carbon is required for nitrogen removal and large savings of oxygen and energy demand can be achieved. The slow-growing bacteria in deammonification are generally grown in biofilms on carriers (as part of the MBBR technology) or in granules and/or flocs.

Today, deammonification technologies for side-stream treatment are state of the art. However, the application of deammonification on mainstream municipal effluent faces several challenges, due to the low temperature, low ammonia concentration and higher COD/NH4-N ratios, which result in competition between the different bacterial consortiums (AOB, Nitrite Oxidising Bacteria (NOB), anammox bacteria and heterotrophs (OHO)), and the requirements for an efficient NOB repression strategy.

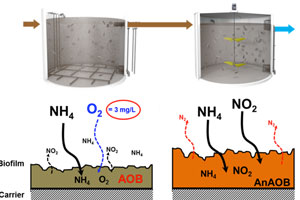

One approach for implementation of deammonification in the mainstream is the two-stage Moving Bed Biofilm Reactor (MBBR) configuration. With the MBBR, the biomass is growing on carriers which are easily and securely retained in the reactor. Hence, the two-stage MBBR system for deammonification enables a compact solution with a high accumulation of nitrifying biomass.

With the two-stage configuration for deammonification, ideal conditions for each of the desired bacteria group can be achieved in separate MBBRs. In the first MBBR, aeration ensures a high DO to achieve efficient nitritation with AOB biofilm, while in the second, a mechanically mixed and anoxic stage, nitrite and ammonia are converted to nitrogen gas through the anammox pathway, without any competition for substrates from oxidising bacteria or heterotrophs. NOB suppression is achieved in the nitritation stage by maintaining thin biofilms and periodically exposing the biomass to strongly suppressing conditions, such as switching the feed from mainstream wastewater to high-strength and high-temperature side-stream water. Hence, NOB can be supressed in the aerated zone without affecting the anammox. Thin biofilms are ensured in the nitritation stage by using the AnoxKTM Z carrier with biofilm thickness control.

Membrane aerated biofilm reactor

This technology was not part of the POWERSTEP project.

Moving Bed Bioreactor (MBBR)

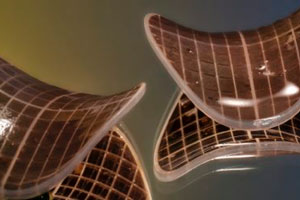

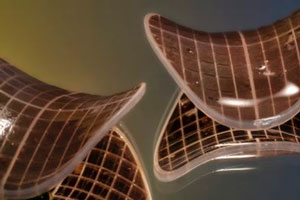

The Moving Bed Biofilm Reactor (MBBR) technology is based on the biofilm principle, with an active biofilm growing on small specially designed plastic carriers. The carriers are designed to provide a large protected surface area for the biofilm to grow and are kept in suspension in the reactor by aeration and/or mixing.

Due to the high biomass content in the biofilms, the MBBR process has a small footprint and high volumetric removal efficiency. The carriers are retained in the reactor by sieves, ensuring that the critical biomass will remain in the reactor also at low temperatures and high hydraulic flows. When needed, the MBBR can be staged in series to promote enrichment of different groups of bacteria dependent on reactor conditions and substrate availability. The MBBR works both for aerobic, anoxic and anaerobic applications.

The MBBR technology has been successfully applied since the 1980´s, treating both industrial and municipal wastewaters. Generally, the MBBR is applied for the biological removal of carbon (through heterotrophic respiration) and nitrogen (through nitrification-denitrification), although the long retention of biomass in the MBBR also makes it advantageous for deammonification, and for the removal of some toxic compounds and micropollutants. The MBBR can also be used in combination with existing activated sludge systems in a hybrid system.

-

Purpose

-

Approach

-

Where?

Nitrification/Denitrification

Biological conversion and elimination of nitrogen in a WWTP can be achieved by the processes of nitrification and denitrification. Usually being in the form of ammonia, nitrogen in wastewater can be converted to nitrate by nitrification, which is realised by specific bacteria (“nitrifiers”) in an autotrophic process using oxygen as electron acceptor. Due to the slow growth rate of nitrifiers, nitrification requires a high sludge age to accumulate this type of bacteria in the activated sludge or biofilm. The high oxygen demand for nitrification (4.3 g O2 per g NH4-N) often defines the size of the aeration system at WWTPs.

The second step of nitrogen conversion is denitrification, which converts nitrate to gaseous nitrogen. Denitrification can be realised by many groups of bacteria, but it requires anoxic conditions to promote the use of chemically bound oxygen of the nitrate. In addition, denitrification requires a carbon source as electron donor, which is an important aspect in WWTP operation. Organic matter in the wastewater acts as carbon source, so that the ratio of bioavailable organics (COD) and nitrogen should be sufficient to guarantee full denitrification. Different configurations are available for WWTP operation such as intermittent denitrification (variation in oxygen supply over time), pre-denitrification with recycling of nitrate to anoxic tanks upstream of nitrification tanks, or cascade denitrification with multiple serial tanks of anoxic and aerobic conditions. Utilisation of microbial sludge as carbon source (“endogenous denitrification”) can also be an option, although the kinetics of this process are limited by hydrolysis of the sludge and thus require higher tank volumes. The dosing of an external carbon source (e.g. acetate) can be a last measure if residual COD for denitrification is limited.

- Nitrification & Denitrification

- Advances in wastewater nitrogen removal by biological processes: state of the art review

-

Purpose

-

Approach

-

Where?

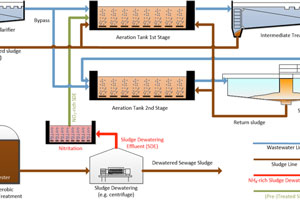

Two-stage activated sludge

The 2-stage treatment concept for municipal WWTPs provides energetic advantages in term of reducing energy demand for aeration and enhancing the energy gain from biogas utilisation in CHP. The concept relies on a high COD-loaded activated sludge tank in the 1st stage where a higher percentage of COD - as compared to single-stage WWTP - is extracted from the wastewater stream with the surplus sludge.

In the 2nd stage which is operated at higher sludge age, nitrification and denitrification take place. Nitrogen removal can be optimised and adjusted to varying operating conditions by bypassing a part of influent wastewater in the 2nd stage for increasing the COD availability for denitrification or by returning a part of the nitrate rich WWTP effluent back to the anoxic zone of the 1st stage. The advantages of 2-stage treatment concepts could be confirmed at several large size WWTPs.

The energetic advantage of the 2-stage treatment configuration can be further increased by integrating a nitritation process to treat the ammonium-rich sludge dewatering effluent in sidestream. The treated wastewater stream can be then reintroduced in the 1st stage, promoting denitritation of the produced nitrite instead of denitrification. The saved COD load is then available for enhanced biogas production in the digester or for improving TN removal at plants with unfavourable TN/COD influent composition. In addition, the implementation of sidestream nitritation decreases operating costs of a 2 stage WWTP due to the better conditions for ammonium oxidation in sidestream than in mainstream (higher oxygen transfer rate).

Whereas sidestream nitritation combined with denitritation in mainstream is nearly energetically equivalent to sidestream anammox (oxygen demand in both cases ~ 1.5 gO2/gNremoved), nitritation exhibits a much more stable operation and lower investment and operation costs for process control.