Technologies

Biological methanation

Biological methanation uses specific microbial metabolisms to generate biomethane out of CO2 and hydrogen. Archaea bacteria are capable to realise this conversion, using CO2 from biogas upgrading and H2 from water electrolysis. The technology has been realised in pilot and full-scale plants up to 1MW of electrical power in electrolysis. The reactor design is crucial for an efficient process to overcome the physical challenge of dissolving H2 into water. The process is scalable and can be operated at full or part-load with short start-up times, operating either on biogas directly or on CO2 from biogas upgrading.

The produced biomethane can be injected to the gas grid for large-scale and long-term storage or used locally, e.g. as fuel for transportation. Besides the energy storage aspect, biological methanation contributes to CO2 recycling, and electrolysis generates valuable by-products such as oxygen and heat at 65oC for direct use at the WWTP.

Catalytical methanation

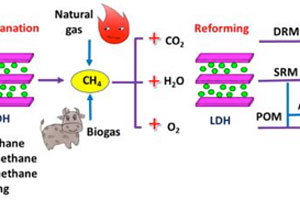

Biogas produced in anaerobic digestion of sewage sludge contains 60-65% methane and 30-35% CO2. If CO2 is separated from biomethane in an upgrading step, it can be used in a Power-to-Gas approach to be converted to biomethane. Utilising hydrogen which is produced in an electrolyser, the process of methanation converts H2 and CO2 into CH4 (Sabatier reaction).

Methanation can be reached in a physico-chemical process with catalytic methanation, or using microbial activity in bio-methanation. Catalytic methanation uses a metal catalyst to enable the chemical reaction, but requires high temperature (350-550°C) and pressure (1-100 bar) and is affected negatively by gas impurities. Currently, catalytic methanation is limited to a CO2 conversion of ca. 80%. Full-scale application of catalytic methanation is still under development, and different reactor configurations and operating modes are tested.

- Sunfire: supplier of catalytic methanation

- Topsoe: supplier of catalytic methanation

- Johnson Matthey: supplier of catalytic methanation

- Methanation in HELMETH Project

- Audi e-gas

- Review paper on methanation technologies

- Review of methanation

- Comparison of biological and catalytic methanation (in German)

- Methanation of CO2 - storage of renewable energy in a gas distribution system

-

Purpose

-

Approach

-

>Where?

Combined heat and power (CHP) plant

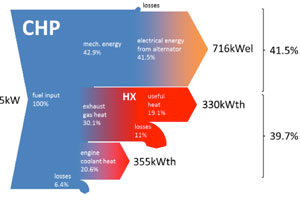

Biogas produced in anaerobic digestion can be valorised on-site in combined heat and power (CHP) plants. These units burn biogas of different quality and convert it into electricity and heat, reaching a high total utilisation efficiency of the energy content in the biogas. CHP plants at WWTPs are usually gas motors, which drive a generator for electricity generation with electrical efficiencies of 35-44% depending on size and load rate. Heat is supplied at two distinct temperature levels: the cooling cycle of the gas motor typically supplies heat at 90°C, while exhaust gas contains heat at >350°C.

Both types of heat can be utilised with heat exchangers, e.g. for heating of anaerobic digestor or buildings or to supply heat for additional processes at the WWTP (e.g. stripping, thermal hydrolysis). Thermal efficiency of usable heat is 41-50% and typically adds up to 85-90% with electrical efficiency. CHP plants should be operated with relatively constant gas quality and in an optimum load range to prevent loss in efficiency.

- Full-scale technico-economical performances of options for heat to electricity conversion in WWTP

- International Energy Agency Report on Combined Heat and Power

- Evaluation of Combined Heat and Power Technologies for Wastewater Facilities

-

Purpose

-

Approach

-

Where?

Gas boiler

This technology was not part of the POWERSTEP project.

Gas scrubbing

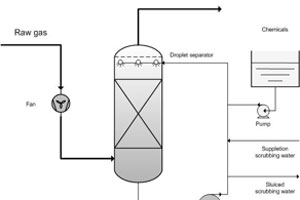

Biogas from anaerobic digestion of sewage sludge contains around 60-65% of methane, 30-35% CO¬2, and other impurities such as N2, H2S, and siloxanes. An alternative to valorisation of this biogas onsite (e.g. in a CHP plant) is the direct injection of gas into the public grid as biomethane. However, gas quality of the injected biomethane has to comply with defined standards of the gas grid operator. A high heating value requires a concentration of >95 Vol-% of methane in the injected gas. This can be achieved by gas scrubbing, which describes the separation of methane and CO2 in a physico-chemical process.

Gas scrubbing can be realised with adsorption using water, amine or other organic scrubbers or pressure-swing adsorption on activated carbon or zeolite. More recently, membrane-based scrubbing or cryogenic scrubbing have been developed. Important features of scrubbers are working pressure and related energy demand, methane content in upgraded gas and methane losses, and heat requirement. Before gas injection, further cleaning can be necessary to remove impurities such as H2S, siloxanes, and other hydrocarbons.

- Report on biogas upgrading technologies (IEA Bioenergy)

- Report on biogas upgrading technologies (SGC)

- Report on biogas upgrading technologies (Energiforsk)

- Gas scrubbing - general

-

Purpose

-

Approach

-

Where?

Load balancing market

The electricity market of today is more dynamic due to the increasing share of renewable energy (e.g. wind, solar) that increases or decreases depending on weather conditions, adding to instability of the electricity grid. Grid system operators have to operate or buy balancing power to level these changes and keep a constant frequency in the alternating current. Hence, large consumers or producers of electricity can offer capacity at the load balancing market and get revenues for both offering capacity reserves and actually using them.

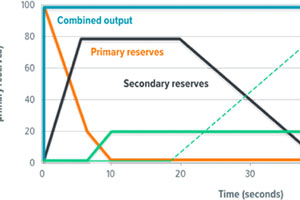

Depending on reaction time and load capacity, primary, secondary and tertiary reserves can be offered with different models of revenue. WWTPs can also offer a certain capacity for load balancing if they are able to cut or increase loads on a remote signal from the grid operator. Minimum loads for the market can be reached by combining several WWTPs in a load cluster.

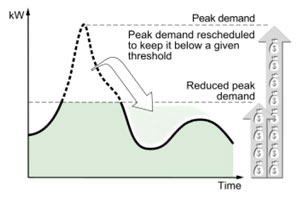

Load shifting

The WWTP is a large consumer of electricity, and the energy demand profile is relatively dynamic over the day depending on the influent load of the plant. As the electricity market of today offers different energy prices at different times of the day and also for maximum peak demand, the time-related shifting of electricity loads can be an option to decrease operational costs for electricity consumption. Maximum peak demand of the WWTP can be reduced by stopping aggregates during times of high electricity prices: pumps, centrifuges, and even aeration systems can be operated dynamically to restrict peak demand and save on costs.

In addition, load shifting can be used to align electricity consumption and production profiles at the WWTP, so that the demand for external electricity from the grid is minimised. Altogether, load shifting can be fully automated depending on electricity consumption at the plant and target profiles for optimised energy costs, following a multi-step strategy to drop off loads of several aggregates in a row if peak demand is reached.

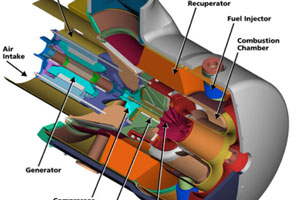

Microgas turbine

This technology was not part of the POWERSTEP project.

-

Purpose

-

Approach

-

Where?

Optimise electricity use

Electricity demand is a major cost driver of WWTP operation, and is also responsible for a high share of the environmental impacts associated with wastewater treatment. Hence, it is of high interest to optimise the use of electricity at a WWTP to minimise both operational costs and environmental impacts of the process.

Options to optimise the use of electricity on-site include the flexible and predictable operation of the plant in terms of electricity demand and production depending on the situation on the public electricity market, following a “smart grid” strategy. Today, market prices of electricity are dynamic over time due to a rising share of renewable sources (e.g. wind, solar), so that WWTP operation can be optimised to utilise this dynamic and minimise electricity costs and revenues. Predicting and adapting electricity demand and production at the WWTP to the hourly market price profile of the next day (“day-ahead market”) enables savings in electricity costs. Storage facilities for biogas or sludge at the WWTP enhance flexibility in operation and facilitate the optimisation of the profile of electricity use and production on-site.